Hydraulic presses for panels

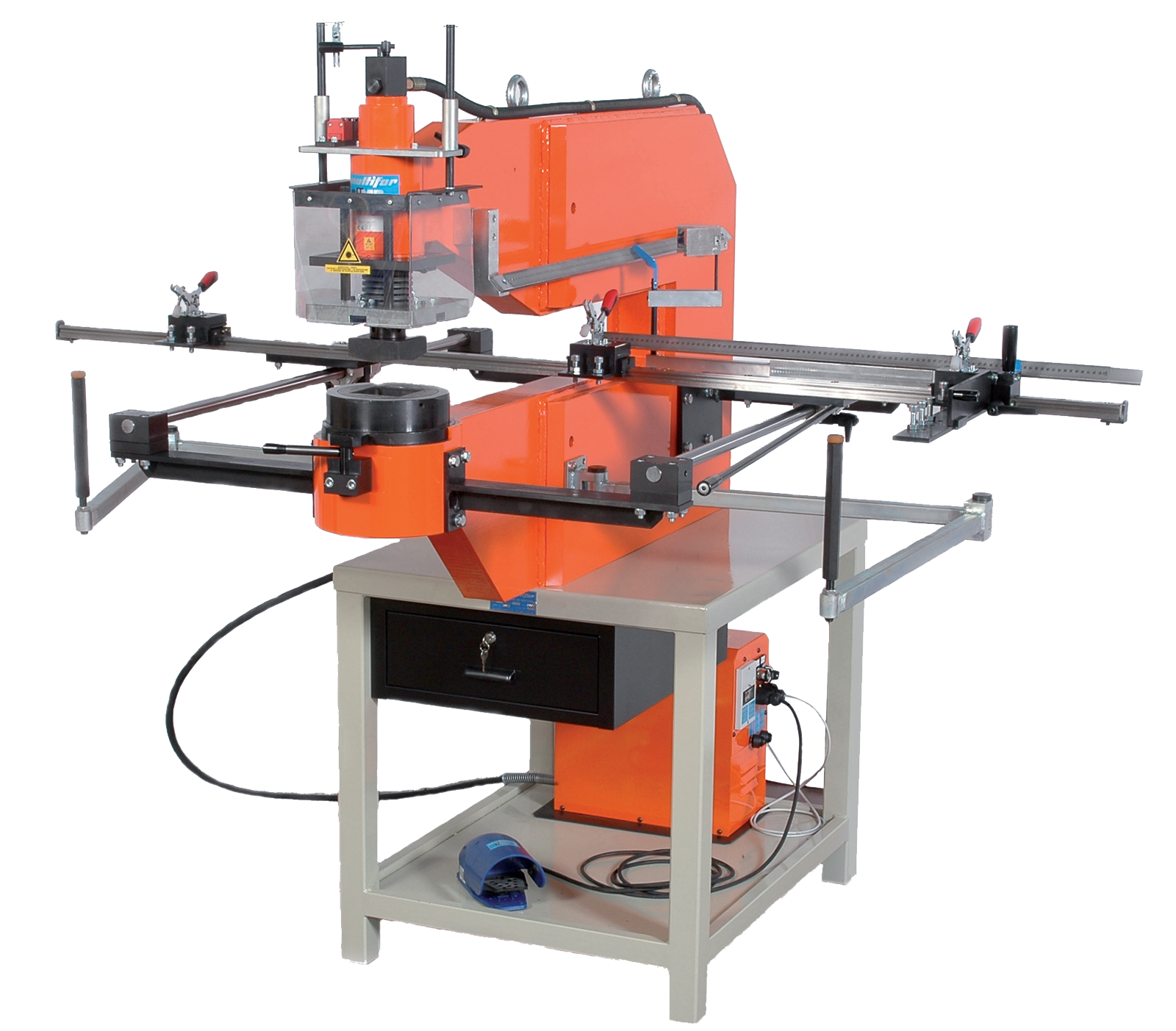

10090EL - 10090ELV - Economic hydraulic punching machine 20 Ton

Light system of brackets regulation with X - Y axis

The hydraulic punching machine 10090EL, is a high power machine with a simple system of brackets regulation for X and Y axis. It has the same characteristics and performance of the hydraulic punching machine 10090L. The axis run is for X axe 1000 mm and for Y axe 900 mm.

These units are studied exclusively for making holes. They are fast and practical to use, thanks to a special system of guides of axis X and Y. This system avoids tracing and the panel board is held up by a mobile support and fixed on X-Y axis.

The version 10090EL has the laser pointing which indicates the center of the hole on the material to punch. The version 10090ELV has the laser

pointing and the visualizer.

Laser pinpoint features

All punching machines are supplied with LASER POINTING which indicates ONLY the centre of the hole to realize on the control board door. The diode is protected inside the stem, to avoid breaking.

Accessories supplied

1 x punch-holder (code 10101L) for round punches up to Ø 40.5 mm max.

1 x die holder flange (code 10191) for round dies up to Ø 40.5 mm max, for square dies of 26 mm max and rectangular or special dies with max dimensions inscribed inside a Ø 37 mm.

2 x set of pullers (code 10141 - 10142) to extract the punch from the sheet.

1 x punch-holder locking ring nut (code 10171).

1 x positioning valve (code 9162).

Max drilling thickness

| Sheets | 2.0 mm |

|---|---|

| Stainless steel | 1.8 mm |

| Aluminium | 5 mm |

| Plastic sheets | 5 mm |

Specifications

| Max outreach | 900 mm |

|---|---|

| Power | 200 kN (20 Ton) |

| Oil capacity needed to make full stroke | 0.18 lt |

| Round hole achievable | Ø 170 mm |

| Max square hole achievable | 138x138 mm |

| Work pressure | 700 bar |

| Length | 2100 mm |

| Width with reference line | 2160 mm |

| Height with base | 1760 mm |

| Light between the punches | 50 mm |

| Punch race | 65 mm |

| X-axis stroke | 1000 |

| Y-axis stroke | 900 mm |

| Weight | About 1000 Kg |

Specifications

| Max outreach | 900 mm |

|---|---|

| Power | 200 kN (20 Ton) |

| Oil capacity needed to make full stroke | 0.18 lt |

| Round hole achievable | Ø 170 mm |

| Max square hole achievable | 138x138 mm |

| Work pressure | 700 bar |

| Length | 1850 mm |

| Width with reference ruler | 3020 mm |

| Height with base | 1680 mm |

| Light between the punches | 50 mm |

| Punch race | 65 mm |

| X-axis stroke | 1500 mm |

| Y-axis stroke | 900 mm |

| Weight | About 1527 Kg |

Max drilling thickness

| Sheets | 2,0 mm |

|---|---|

| Stainless steel | 1,8 mm |

| Aluminum | 5 mm |

| Plastic laminates | 5 mm |

10090L - 10090 LV - 20 tons hydraulic punching machine

The MULTIFOR hydraulic punching machines, which combine high power with compact dimensions, are built to resolve the problems of making holes in panels, lids, sheet steel, aluminium strip or plastic. These units are studied exclusively for making holes. They are quick and practical as they avoids marks working on a special rail sysstem of X-Y axis, on which the panel board is fixed. The pre-hole is not necessary.

With the special punches, you can realize the following holes: round, square, rectangular, shaped, round with more holes, square with round holes, rectangular with round holes, tools for ventilation slots, etc. The MULTIFOR punching machines can be connected with a rapid connector to the MULTIFOR electric units. These units can be also used in small workshop due to their versatility and small size.

All our hydraulic punching machines are equipped with carter protection, safety micro switch and electric micro end-stroke. The dies assembly is very simple and it is not necessary to take away the panel board. In order to reduce the working cycles, a rise stroke regulator allows to reduce the opening between the punch and the die.

Accessories supplied

1 x metal base 10100/90

1 x punch-holder (code 10101L) for round punches up to Ø 40.5 mm max.

1 x die holder flange (code 10191) for round dies up to Ø 40.5 mm max, for square dies of 26 mm max and rectangular or special dies with max dimensions inscribed inside a Ø 37 mm.

2 x set of pullers (code 10141 - 10142) to extract the punch from the sheet.

1 x punch-holder locking ring nut (code 10171).

1 x positioning valve (code 9162).

Fill out our contact form for information on hydraulic punching machines and available accessories